Waste management

At SOLMED Alliance we are very clear that making a responsible and sustainable use of our waste is key to caring for the planet. That is why we offer a wide range of waste management services, always from the perspective of respect for the environment.

Our philosophy is clear: to apply the latest waste treatment technologies to optimise the reuse of waste.

We aim to have a positive impact on the environment and, in doing so, our number one priority is to make sustainable use of the waste we manage.

The goal: 0% landfill waste

Innovation for sustainability

Waste treatment: directly at source

Infectious hospital waste

H Series

Hospitals, Clinics, Treatment Centres, Laboratories, Waste Management Centres

Municipal solid waste

MO Series

Restaurants, hotels, bars, residences, homes, resorts, shopping centres, airports, customs, ports, construction sites, markets, industries and onshore.

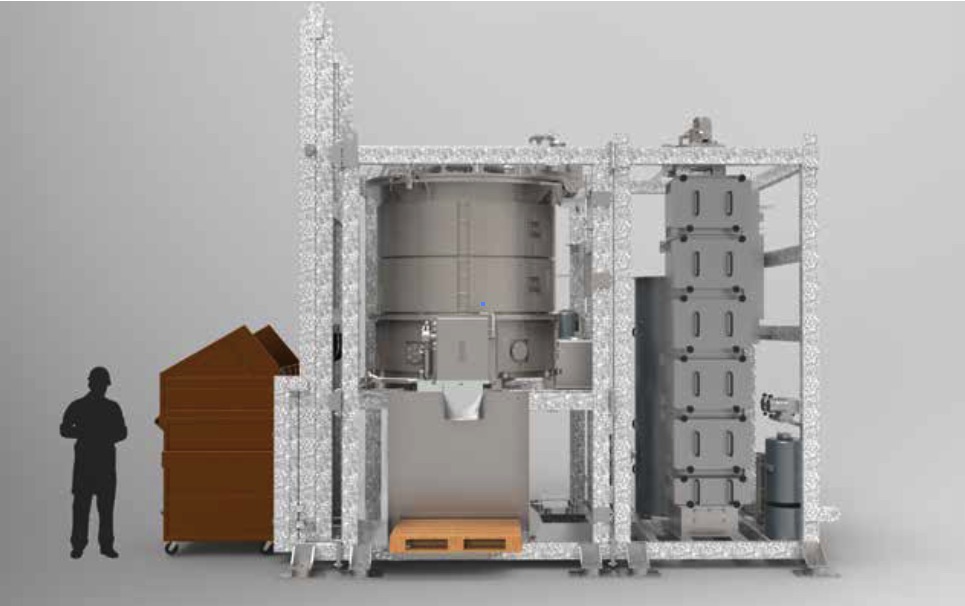

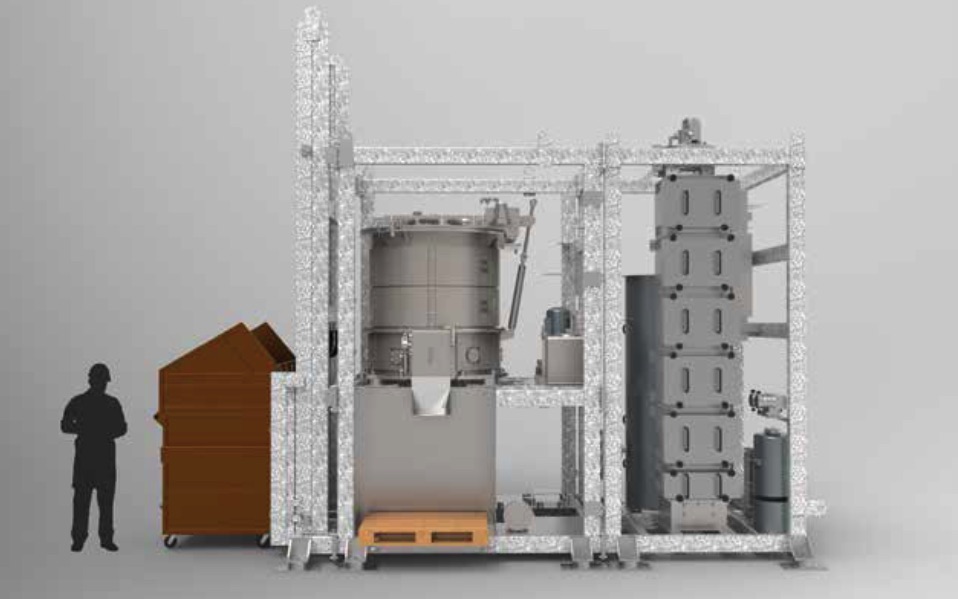

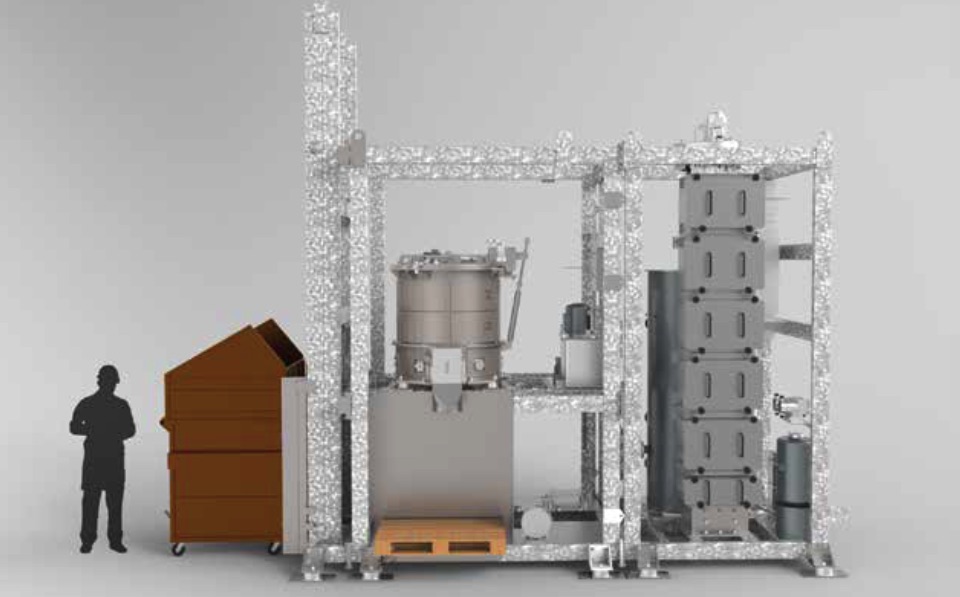

On-site treatment

MOB Series

Military bases, humanitarian camps, field hospitals, airports, customs, ports, resorts, construction sites, onshore, markets, shopping centres, industry.

Offshore treatment

NV Series

Private yachts, offshore platforms, merchant ships, cruise ships, oil tankers, ferries, military vessels

Waste characteristics

The equipment transforms waste into a reusable material by transforming a hazardous waste into a product with the LER Code: (European Waste List) 19.12.10 – 20.03.01.

Certifications

The equipment is designed for the treatment of waste of different types and composition resulting in sterilisation, physical modification, volume reduction, dehydration and weight reduction.

Waste loading

The rotor gradually accelerates to crush the material and the temperature quickly reaches 100ºC.

Evaporation

Overheating

Sterilisation or Pasteurisation

Cooling

Vacuum bag unloading

The final outcome

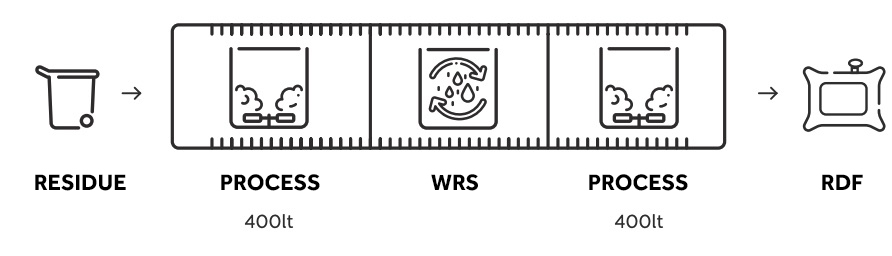

Valorisation of fluff as a waste derived fuel

Uses of the derived waste

Fuels

Controlled incineration

Power generation

Cement plants

Odourless, pasteurised and fully processed.

Cycle time with technology under 30 minutes

At the end of the treatment, the outgoing product is generally considered a “fluff”. It is completely unrecognisable, odourless and completely sterilised in all its parts; but above all, with a 50% reduction in weight and 80% reduction in volume.

The waste can remain for up to 90 days without the need for storage or refrigeration as it is completely pasteurised. In addition, they do not emit odours or produce leachate. These characteristics guarantee not only benefits in terms of safety, long-term handling and storage of a stable product, but also allow considerable savings in logistics, not only from an economic but also from a practical and environmental point of view (less material disposed of means a reduction in costs and consequently in the number of transports, giving an overall environmental benefit).

-80% Volume

-50% Weight*

*according to input humidity

Advantages of this technology

Heating power

The special vacuum packaging reduces the volume of treated waste by up to 80%. The technology pulverises and dehydrates the waste, resulting in RDF (refuse derived fuel) with LER Code 19.12.10 or 20.03.01.

Emission-free

Liquids in the waste are separated and condensed.

No water consumption

Can be reduced to 0

No segregation

No need to separate waste, saves time

Safe storage

Dust-free, odourless and non-fermenting

Easy to use

No special licence required

Volume reduction

Up to 80%.

No refrigeration room required

Quick cycle

The processing cycle takes less than 30 minutes.

Energy independent

Models:

| Technical details | |

|---|---|

| 5000 litres of residue | |

| hospital waste | 500 a 600 kg/h |

| treatment chamber volume [lt] | 5000 |

| dry weight of the machine [kg] | 16000 |

| machine footprint [mm – h] | 8000×2500-6500 |

| electrical panel weight [kg] | 1200 |

| electrical panel fooprint [mm] | 1600x800x2100 |

| total installed power [kw] | 520 |

| rated engine power [kw] | 500 |

| rated current [a] | 600 |

| current spike [a] | 750 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 2000 litres of waste | |

| hospital waste | 250 to 350 kg/h |

| treatment chamber volume [lt] | 2000 |

| dry weight of the machine [kg] | 14000 |

| machine footprint [mm – h] | 6700×2500-6500 |

| electrical panel weight [kg] | 1000 |

| electrical panel footprint [mm] | 1600x800x2100 |

| total installed power [kw] | 360 |

| rated engine power [kw] | 350 |

| rated current [a] | 400 |

| current spike [a] | 480 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 1000 litres of waste | |

| hospital waste | 150 to 200 kg/h |

| treatment chamber volume [lt] | 1000 |

| dry weight of the machine [kg] | 12000 |

| machine footprint [mm – h] | 6700×2500-5900 |

| electrical panel weight [kg] | 800 |

| electrical panel footprint [mm] | 1600x800x2100 |

| total installed power [kw] | 260 |

| rated engine power [kw] | 250 |

| rated current [a] | 300 |

| current spike [a] | 360 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

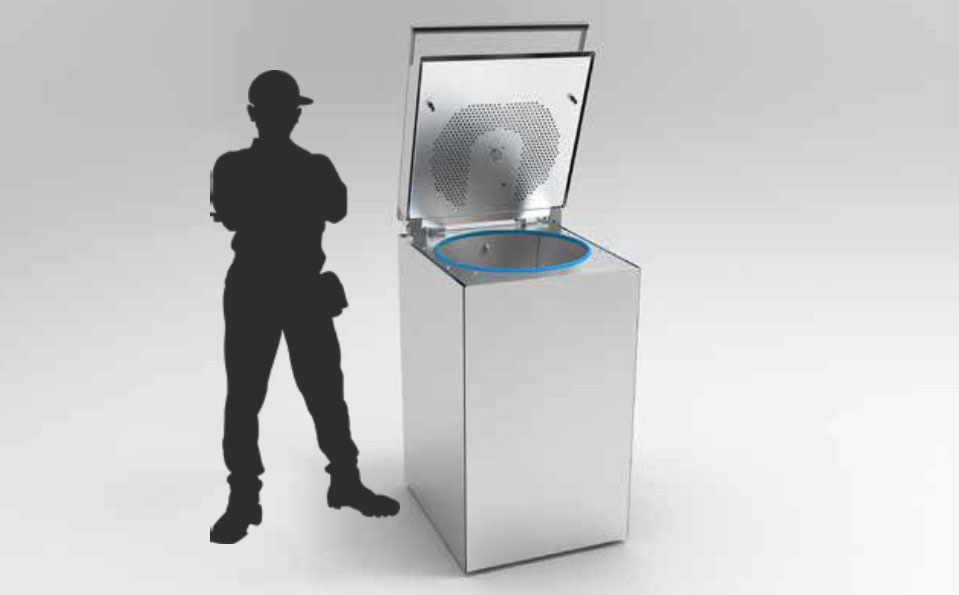

| 400 litres of waste | |

| hospital waste | 60 to 80 kg/h |

| treatment chamber volume [lt] | 400 |

| dry weight of the machine [kg] | 2200 |

| machine footprint [mm – h] | 2300×1500-1800 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 100 |

| rated engine power [kw] | 85 |

| rated current [a] | 120 |

| current spike [a] | 150 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 200 litres of waste | |

| hospital waste | 30 to 40 kg/h |

| treatment chamber volume [lt] | 200 |

| dry weight of the machine [kg] | 1500 |

| machine footprint [mm – h] | 1950×1200-1400 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 65 |

| rated engine power [kw] | 60 |

| rated current [a] | 95 |

| current spike [a] | 120 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

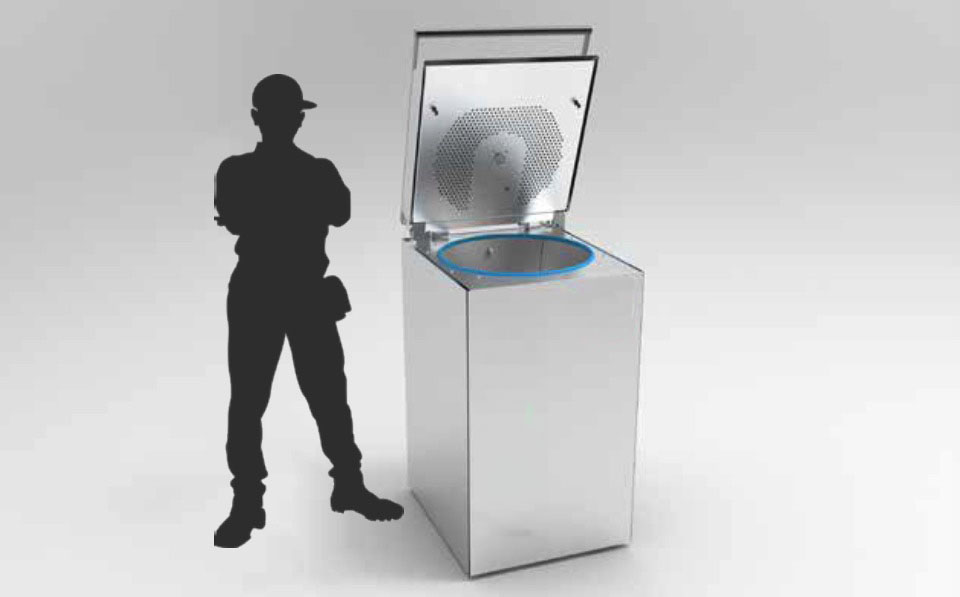

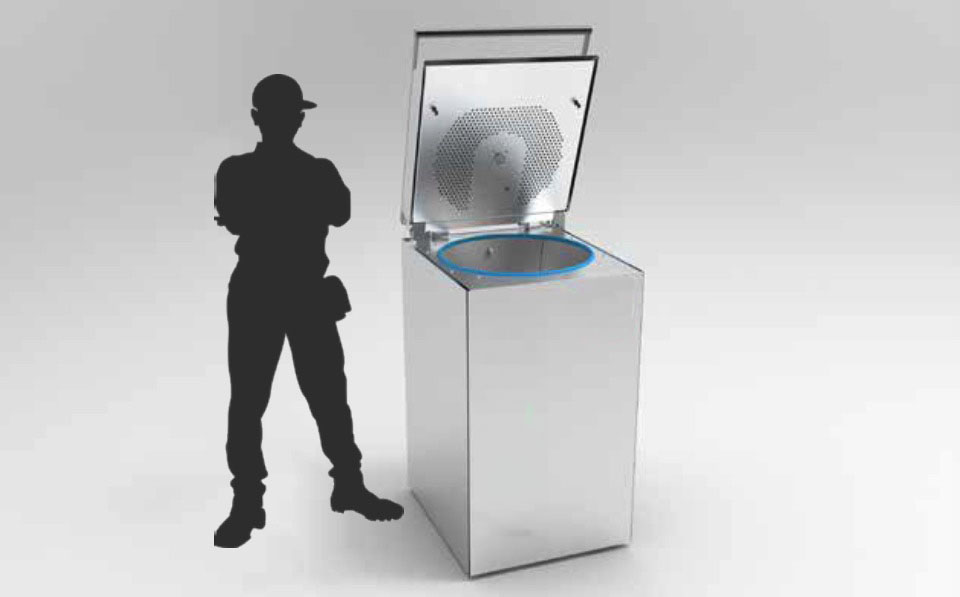

| 100 litres of waste | |

| hospital waste | 15 to 20 kg/h |

| treatment chamber volume [lt] | 100 |

| dry weight of the machine [kg] | 1100 |

| machine footprint [mm – h] | 1500×1100-1400 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 55 |

| rated engine power [kw] | 50 |

| rated current [a] | 70 |

| current spike [a] | 80 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| H50 | |

| treatment chamber volume [lt] | 50 |

| dry weight of the machine [kg] | 250 |

| electrical panel footprint [mm] | 700x700x1100 |

| total installed power [kw] | 10 |

| waste [kg/h] | 8 – 12 |

| H25 | |

| treatment chamber volume [lt] | 25 |

| dry weight of the machine [kg] | 110 |

| electrical panel footprint [mm] | 700x600x900 |

| total installed power [kw] | 2.8 |

| waste [kg/h] | 4 – 6 |

| Technical details | |

|---|---|

| 5000 liters of waste | |

| organic waste | 500 to 600 kg/h |

| municipal waste | 1500 to 1800 kg/h |

| treatment chamber volume [lt] | 5000 |

| dry weight of the machine [kg] | 16000 |

| machine footprint [mm – h] | 8000×2500-6500 |

| electrical panel weight [kg] | 1200 |

| electrical panel footprint [mm] | 1600x800x2100 |

| total installed power [kw] | 520 |

| rated engine power [kw] | 500 |

| rated current [a] | 600 |

| current spike [a] | 750 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 2000 liters of waste | |

| organic waste | 250 to 350 kg/h |

| municipal waste | 600 to 800 kg/h |

| treatment chamber volume [lt] | 2000 |

| dry weight of the machine [kg] | 14000 |

| machine footprint [mm – h] | 6700×2500-6500 |

| electrical panel weight [kg] | 1000 |

| electrical panel footprint [mm] | 1600x800x2100 |

| total installed power [kw] | 360 |

| rated engine power [kw] | 350 |

| rated current [a] | 400 |

| current spike [a] | 480 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 1000 liters of waste | |

| organic waste | 150 to 200 kg/h |

| municipal waste | 250 to 300 kg/h |

| treatment chamber volume [lt] | 1000 |

| dry weight of the machine [kg] | 12000 |

| machine footprint [mm – h] | 6700×2500-5900 |

| electrical panel weight [kg] | 800 |

| electrical panel footprint [mm] | 1600x800x2100 |

| total installed power [kw] | 260 |

| rated engine power [kw] | 250 |

| rated current [a] | 300 |

| current spike [a] | 360 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 400 liters of waste | |

| organic waste | 60 to 80 kg/h |

| municipal waste | 100 to 150 kg/h |

| treatment chamber volume [lt] | 400 |

| dry weight of the machine [kg] | 2200 |

| machine footprint [mm – h] | 2300×1500-1800 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 100 |

| rated engine power [kw] | 85 |

| rated current [a] | 120 |

| current spike [a] | 150 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 200 liters of waste | |

| organic waste | 30 to 40 kg/h |

| municipal waste | 40 to 80 kg/h |

| treatment chamber volume [lt] | 200 |

| dry weight of the machine [kg] | 1500 |

| machine footprint [mm – h] | 1950×1200-1400 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 65 |

| rated engine power [kw] | 60 |

| rated current [a] | 95 |

| current spike [a] | 120 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| 100 liters of waste | |

| organic waste | 15 to 20 kg/h |

| municipal waste | 20 to 40 kg/h |

| treatment chamber volume [lt] | 100 |

| dry weight of the machine [kg] | 1100 |

| machine footprint [mm – h] | 1500×1100-1400 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 55 |

| rated engine power [kw] | 50 |

| rated current [a] | 70 |

| current spike [a] | 80 |

| electricity consumption [kw/kg] | 0.4 – 0.6 |

| Technical details | |

|---|---|

| H50 | |

| treatment chamber volume [lt] | 50 |

| dry weight of the machine [kg] | 250 |

| electrical panel footprint [mm] | 700x700x1100 |

| total installed power [kw] | 10 |

| waste [kg/h] | 8 – 12 |

| H25 | |

| treatment chamber volume [lt] | 25 |

| dry weight of the machine [kg] | 110 |

| electrical panel footprint [mm] | 700x600x900 |

| total installed power [kw] | 2.8 |

| waste [kg/h] | 4 – 6 |

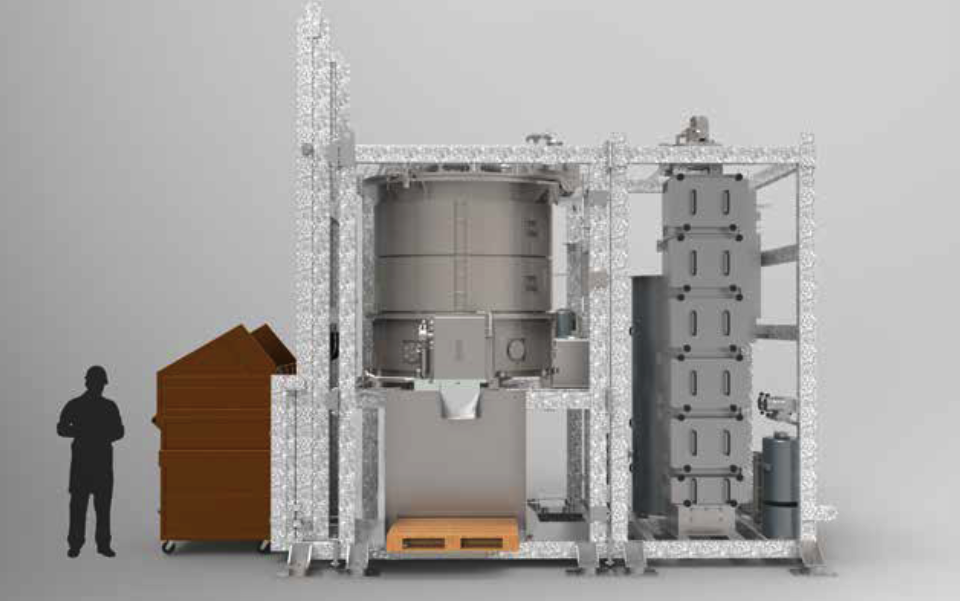

| Technical details | |

|---|---|

| 200 liters of waste | |

| organic waste | 30 to 40 kg/h |

| municipal waste | 40 to 80 kg/h |

| 400 liters of waste | |

| organic waste | 60 to 80 kg/h |

| municipal waste | 100 to 150 kg/h |

| 200 or 400 liters in container | |

| 1 unit: 200 or 400 liters | |

| 1 radiator type cooling unit | |

| 3 water tanks | |

| 1 electrical control panel | |

| Internal lighting system | |

| NOTE | |

| treatment capacities calculated assuming: | |

| a density of 180 kg/m3 and 50% humidity for urban waste | |

| Technical details | |

|---|---|

| 400 liters of waste | |

| organic waste | 60 to 80 kg/h |

| municipal waste | 100 to 150 kg/h |

| 400 liters in container | |

| 1 Unit: 400 liters | |

| 1 radiator type cooling unit | |

| 3 water tanks | |

| 1 diesel generator with 8 hours autonomy | |

| 1 electrical control panel | |

| Internal lighting system | |

| NOTE | |

| treatment capacities calculated assuming: | |

| a density of 180 kg/m3 and 50% humidity for urban waste | |

| a density of 100 kg/m3 and 30% humidity for medical waste | |

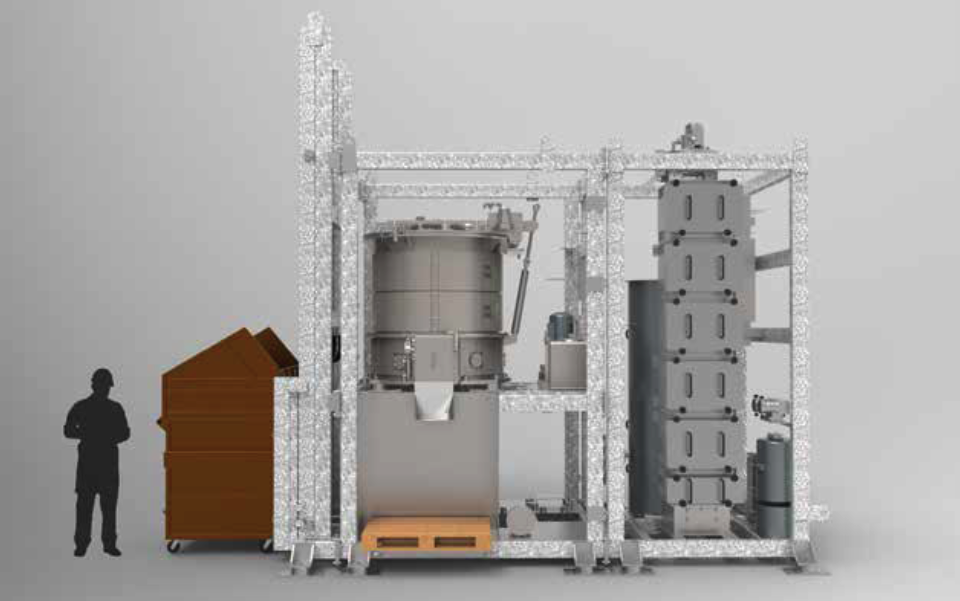

| Technical details | |

|---|---|

| 400 liters of waste | |

| organic waste | 60 to 80 kg/h |

| municipal waste | 100 to 150 kg/h |

| 400 liters in container | |

| 2 Units: 400 liters | |

| 1 radiator type cooling unit | |

| 3 water tanks | |

| 1 electrical control panel | |

| Internal lighting system | |

| NOTE | |

| treatment capacities calculated assuming: | |

| a density of 180 kg/m3 and 50% humidity for urban waste | |

| a density of 100 kg/m3 and 30% humidity for medical waste | |

| Technical Details | |

|---|---|

| 400 liters of waste | |

| organic waste | 60 to 80 kg/h |

| municipal waste | 100 to 150 kg/h |

| treatment chamber volume [lt] | 400 |

| dry weight of the machine [kg] | 2200 |

| machine footprint [mm – h] | 2300×1500-1800 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 100 |

| rated engine power [kw] | 85 |

| rated current [A] | 120 |

| current spike [A] | 150 |

| electric consumption [kw/kg] | 0.4 – 0.6 |

| Technical Details | |

|---|---|

| 200 liters of waste | |

| organic waste | 30 to 40 kg/h |

| municipal waste | 40 to 80 kg/h |

| treatment chamber volume [lt] | 200 |

| dry weight of the machine [kg] | 1500 |

| machine footprint [mm – h] | 1950×1200-1400 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 65 |

| rated engine power [kw] | 60 |

| rated current [A] | 95 |

| current spike [A] | 120 |

| electric consumption [kw/kg] | 0.4 – 0.6 |

| Technical Details | |

|---|---|

| 100 liters of waste | |

| organic waste | 15 to 20 kg/h |

| municipal waste | 20 to 40 kg/h |

| treatment chamber volume [lt] | 100 |

| dry weight of the machine [kg] | 1100 |

| machine footprint [mm – h] | 1500×1100-1400 |

| electrical panel weight [kg] | 450 |

| electrical panel footprint [mm] | 1000x660x2000 |

| total installed power [kw] | 55 |

| rated engine power [kw] | 50 |

| rated current [A] | 70 |

| current spike [A] | 80 |

| electric consumption [kw/kg] | 0.4 – 0.6 |

| Technical Details | |

|---|---|

| NV30 | |

| treatment chamber volume [lt] | 50 |

| dry weight of the machine [kg] | 250 |

| electrical panel footprint [mm] | 700x700x1100 |

| total installed power [kw] | 10 |

| waste [Kg/h] | 8 – 12 |

| Technical Details | |

|---|---|

| NV10 | |

| treatment chamber volume [lt] | 25 |

| dry weight of the machine [kg] | 110 |

| electrical panel footprint [mm] | 700x600x900 |

| total installed power [kw] | 2.8 |

| waste [Kg/h] | 4 – 6 |

Servicios de gestión y tratamiento de residuos

We protect you and the environment

We have everything you need for comprehensive waste management: transport, storage, treatment and recovery of waste, as well as the reuse of raw materials, and the final disposal of waste in a controlled and safe manner. We also offer a wide range of high added value industrial cleaning services.

In addition, SOLMED Alliance offers complete urban cleaning services. Our projects are based on our own experience in managing camps, municipalities and cities of between 3,000 and 1,500,000 inhabitants, with routes covering areas of 300 km2/day. We are able to handle an average waste collection volume of 1,800 tonnes.